Turning a prototype into a market-ready product is a significant milestone for any innovator. While a prototype helps validate concepts and initial designs, scaling it into a fully realized product involves navigating several complex stages. Each step in this process—from refining designs to securing production channels—plays a crucial role in transforming an idea into a tangible, successful product. In this blog post, we’ll break down the essential steps for scaling a prototype into a market-ready product.

1. Refine and Validate the Prototype

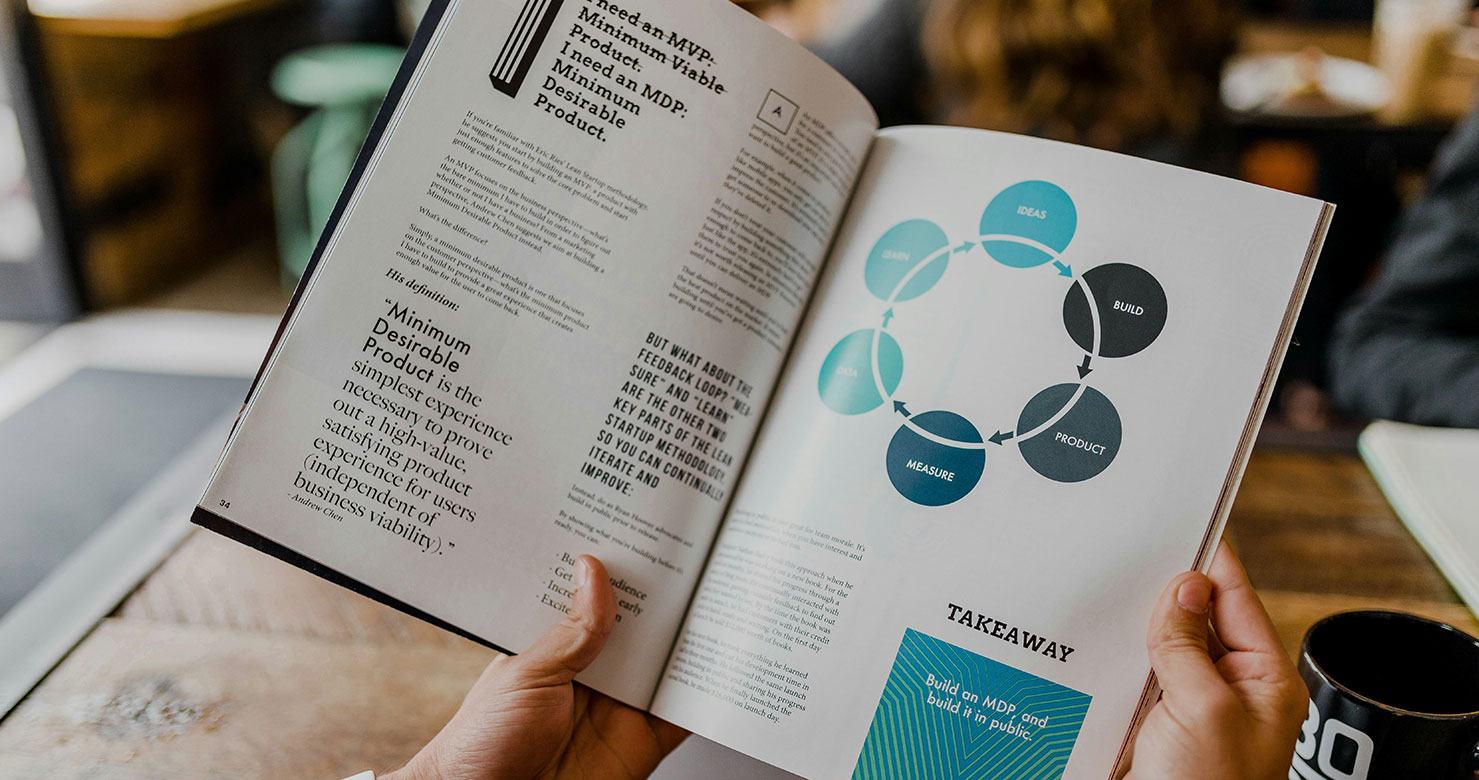

After creating an initial prototype, it’s essential to refine it based on user feedback and testing. This step is about ensuring that the prototype aligns with the target market’s needs and addresses any pain points effectively.

- Collect Feedback: Engage with early users or potential customers to gather feedback. Ask for insights into usability, design, and functionality to identify potential improvements.

- Iterate and Improve: Use this feedback to refine the prototype. Each iteration should bring the product closer to the final vision and improve its functionality, usability, and appeal.

2. Conduct Market Research and Competitor Analysis

Understanding the market landscape is key to positioning your product effectively. Conducting thorough market research will inform your product design and go-to-market strategy, helping to differentiate your offering.

- Identify Market Needs: Analyze the specific needs of your target audience and ensure that your product aligns with them.

- Study Competitors: Look into competitors’ products to identify what works, what doesn’t, and where your product can offer unique value. Use these insights to refine your product and position it strategically.

3. Finalize the Design for Manufacturing

Prototypes are often created with rapid iteration and testing in mind, which may not translate efficiently to mass production. This step involves adjusting the design to be both scalable and cost-effective for manufacturing.

- Design for Manufacturing (DFM): Work with engineers to adapt the prototype design for large-scale production. DFM ensures that your product is manufacturable without compromising on quality or design integrity.

- Select Materials: Choose materials that balance durability, cost, and aesthetics. The right materials enhance your product’s quality and help you stay within budget constraints.

4. Source Reliable Manufacturing Partners

Choosing the right manufacturing partners is crucial to producing high-quality products at scale. Look for partners who have experience in your product category, a strong track record, and an understanding of your design and quality standards.

- Assess Capabilities: Verify that potential manufacturers can handle the volume, complexity, and specifications of your product.

- Request Samples: Work with your manufacturing partner to produce sample runs. This step allows you to assess quality and make any necessary adjustments before full-scale production.

5. Develop a Quality Control Process

As production scales, maintaining consistent quality can be challenging. Implementing a robust quality control (QC) process ensures that every product meets your standards, protecting your brand reputation and satisfying customers.

- Establish Standards: Define clear quality standards for every component and process, from raw materials to final assembly.

- Regular Inspections: Conduct regular inspections at different stages of production, including random checks on completed units. This proactive approach minimizes the risk of defective products reaching the market.

6. Plan Your Supply Chain and Logistics

Efficient supply chain management is essential for timely production and delivery. This step involves planning and organizing everything from raw material sourcing to final delivery, with a focus on efficiency and reliability.

- Inventory Management: Develop an inventory strategy that balances demand with production capacity, minimizing storage costs and avoiding stockouts.

- Logistics Planning: Choose reliable logistics partners to handle shipping and warehousing. Assess their track records for on-time deliveries and cost-effectiveness.

7. Test and Validate at Scale

Before going to market, conduct pilot tests to validate product performance, customer satisfaction, and logistics processes at scale. These tests help identify potential issues and fine-tune your approach.

- Pilot Launch: Release a limited batch to a select audience to gather feedback on product performance and logistics efficiency.

- Adjust as Needed: Use insights from the pilot launch to refine processes, product design, and customer support before the full-scale launch.

8. Prepare for Marketing and Sales

A strong go-to-market strategy is vital to building awareness, generating interest, and driving sales. This phase includes finalizing your branding, creating a compelling value proposition, and developing a marketing strategy.

- Define Your Unique Value Proposition: Clearly communicate what makes your product unique and why customers should choose it over competitors.

- Build a Marketing Campaign: Plan marketing tactics such as social media campaigns, influencer partnerships, and email marketing to reach your target audience and generate excitement.

9. Launch and Monitor Customer Feedback

Once you’re ready to go to market, keep a close eye on customer feedback. This helps you identify any issues quickly and adapt your strategy as needed.

- Listen and Respond: Engage with customers through social media, surveys, and customer support to address concerns and gather feedback.

- Continuous Improvement: Use feedback and data analytics to identify areas for improvement, whether in product features, user experience, or customer service.

Scaling from a prototype to a fully-fledged product is a complex but rewarding journey. By carefully refining the design, sourcing quality manufacturers, implementing quality control, and crafting a strategic go-to-market approach, you can set the stage for a successful product launch. Each step builds on the previous one, ultimately helping you transform your idea into a tangible product that meets customer needs and stands out in the marketplace. With dedication, adaptability, and a clear roadmap, you can bring your vision to life and achieve long-term success.